This is the follow up I had promised on the making and usage of the plane design I spoke of in the previous post. (better late than never)

Bottom line: I count this a successful design, experiment & tool, but don't think I'll be making/using solid surface material again for a plane. I just don't enjoy the process. I'd like to make the same body in wood sometime though.

If a potential planemaker was already tooled up for working the stuff with a CNC router per the cabinet shop norm, they could come up with some straightforward paths and offer a nice line of smoothers with their scraps, with a pretty minimal investment of effort. The material is very dense, and feels nice.

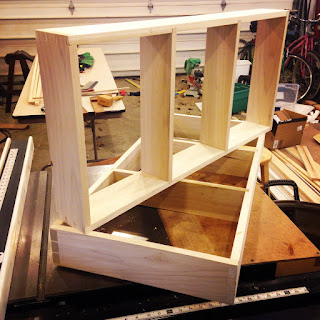

I'm not planning on detailing the process, but have included photos of steps along the way. If you have a specific question, just leave a comment. Most everything was done using 4 tools table saw, pattern cutting router bit, stationary belt sander, and drill mounted drum sander.

Prior to this build, I made a prototype in a block of Cyprus. I really like the two halves method of plane making. I think this has a lot of potential.

Lessons Learned:

- Geometric Design. I'm really pleased with how it turned out. All-in-all it handles well (perhaps a bit toe heavy) and looks good to me.

- Cross pin. I sort of trivialized that I could make this fit around the other parameters like wall profile and mouth opening later on. This was a mistake, and meant that in the end I had to place it a little closer to the iron than desired, making the wedge thinner than I would have preferred.

- Wedge Shape, I sort of thought this would be simple to design on the fly as well. It wasn't. getting the shape that fit the body and could still be tapped in the directions needed etc.

- Planing angle. I bedded this plane ~55° It makes it a bit harder to push, but cuts well in anything I've thrown it's way (in most any direction)

Challenges:

Materials

This project was 80% about the materials, so it's no surprise that this is where I have the most to say.

- I didn't have true Corian® but some knock-off solid surface product (my source was leftovers from an auction). The main differences being that it has tiny bubbles (not as good as the Don Ho version) that come through when you work into it. I also suspect that Corian® is more uniform in thickness.

- The stuff I had, wasn't parallel and/or flat, which didn't become apparent until I went to glue up, this left a line. If I had used matching epoxy it would've blended nicely.

- "Corian" machines very nicely with carbide tools, like routing MDF I suppose. That said, I had quite a bit of chipout in the mouth area from the table saw, this was filled with epoxy, so no impact on function, but again visible.

- While not cold as steel, it's not quite as warm as wood. This might again be an issue with the non-genuine Corian®

- Its got a really nice heft to it.

|

| Routing Template |

- Corian is messy...like 5 8yr old boys at a sleepover messy.

- Even though I know it's less dulling than my cast iron baileys, I feel apprehension installing/removing the iron. Feels like working without a net over concrete.

Maintaining symmetry

Maintaining symmetry

Since only the bed and sole are flat in the end, careful layout and operation sequencing was important to make sure that the needed work could be done to keep things symmetric.